Electromechanical Services: An Overview and Their Applications in Commercial and Industrial Establishments

Introduction to Electromechanical Services

Electromechanical services encompass a diverse range of systems that integrate electrical and mechanical components to operate effectively. These systems are pivotal in modern technological environments, where both electrical and mechanical tasks must be performed to achieve optimal productivity. By bridging the gap between electrical engineering and mechanical systems, electromechanical services have become essential in enhancing the functionality of various applications across multiple sectors.

The importance of electromechanical systems can be observed in industries such as manufacturing, aerospace, automotive, and robotics. For instance, in manufacturing plants, electromechanical systems are utilized for automation processes, intricate machinery operations, and precise control systems. These systems ensure that machinery functions seamlessly, contributing to operational efficiency and productivity. Additionally, they offer the reliability required for high-stakes environments like aerospace, where precision is paramount for safety and performance.

An electromechanical system typically consists of components such as actuators, sensors, controllers, and power systems, all of which work in conjunction to perform specific tasks. Actuators convert electrical energy into mechanical motion, enabling machinery to operate as desired, whereas sensors provide essential feedback on system performance. Controllers integrate these elements to manage operations effectively, making adjustments based on real-time data. This triad of components highlights the sophistication and interplay of mechanical and electrical disciplines within electromechanical services.

The evolution of technology has led to advances in electromechanical systems, driving innovation in automation and industrial applications. In today’s fast-paced commercial landscape, businesses are increasingly reliant on these systems to streamline operations, reduce downtime, and enhance overall performance. In the following sections, we will delve deeper into specific applications and benefits that stem from the implementation of electromechanical services in both commercial and industrial settings.

Key Components of Electromechanical Systems

Electromechanical systems are integral to the operation of various commercial and industrial applications. These systems seamlessly combine electrical and mechanical components to perform functions ranging from simple tasks to complex automation processes. Understanding the key components that constitute electromechanical systems is essential for appreciating how they operate effectively.

Central to electromechanical systems are motors, which convert electrical energy into mechanical energy. These motors are responsible for driving different types of machinery and equipment, making them fundamental in achieving desired movements or operations. Whether in conveyor belts or robotic arms, motors serve as the primary source of locomotion and force exertion.

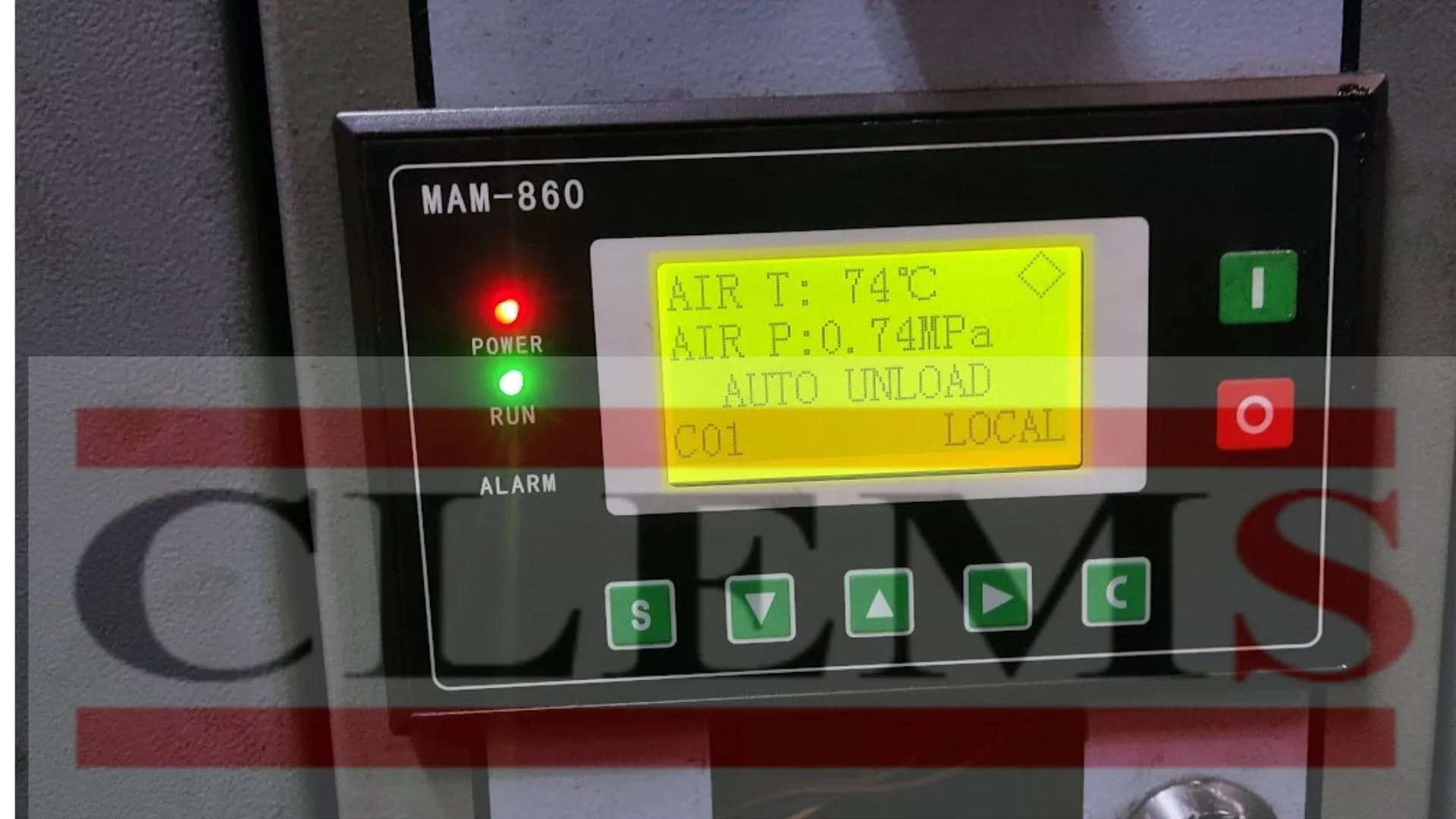

Complementing the motors are sensors, which are crucial for monitoring various parameters such as temperature, pressure, and position. Sensors provide real-time feedback to the system, ensuring that it operates within specified limits. Their ability to detect changes in the environment enables proactive adjustments, facilitating safety and efficiency in processes.

Actuators also play a significant role in electromechanical systems. They take signals from the controllers and convert them into physical movement. This interaction is vital for the execution of commands generated from the system, enabling responsive actions that align with operational requirements.

Controllers serve as the brain of electromechanical systems, processing inputs from sensors and directing motors and actuators accordingly. By utilizing software algorithms, controllers can manage complex tasks, ensuring optimal performance and synchronization among various components.

Finally, the power supply units provide the necessary energy for the smooth operation of the entire system. The reliability and efficiency of the power supply are paramount, as they directly influence the performance of motors and other connected elements.

In essence, the interaction among motors, sensors, actuators, controllers, and power supply units forms a cohesive electromechanical system, facilitating automation and enhancing operational capabilities in diverse industries.

Importance of Electromechanical Services in Commercial Establishments

Electromechanical services play a pivotal role in modern commercial establishments, offering an array of applications that enhance operational efficiency and overall functionality. One of the most significant areas where electromechanical systems are essential is in HVAC (Heating, Ventilation, and Air Conditioning) systems. These systems are crucial for maintaining comfortable indoor environments, and their electromechanical components ensure precise temperature control and improved energy efficiency. By optimizing HVAC operations, businesses can substantially lower energy consumption, thereby resulting in significant cost savings on utility bills.

Moreover, automated lighting control systems, which integrate electromechanical technologies, contribute to energy conservation and enhance safety. These systems adjust lighting based on occupancy and natural light levels, ensuring that energy is used judiciously. Such automation not only reduces operational costs but also extends the lifespan of lighting fixtures, aligning with sustainability goals that many businesses are striving to achieve.

Security systems also benefit from electromechanical services. Advanced surveillance, access control, and alarm systems rely heavily on electromechanical components to function effectively. The integration of these systems enhances the overall safety and security of commercial establishments, protecting both assets and personnel. Furthermore, the real-time monitoring capabilities provided by these systems enable a swift response to security threats, thus preserving the integrity of the business environment.

Electromechanical services also play a significant role in comprehensive facilities management solutions. By employing various automated systems for monitoring and control, commercial establishments can improve operational effectiveness. Regular maintenance and smart integration of electromechanical devices facilitate the identification of inefficiencies, leading to proactive management of resources. The combination of energy efficiency and operational enhancement underscores the importance of electromechanical services in today’s commercial arenas. Such services ultimately foster an environment conducive to productivity while ensuring a lower environmental footprint.

Impact of Electromechanical Services in Industrial Settings

Electromechanical services play a vital role in modern industrial environments, providing key solutions that enhance efficiency and productivity. These services encompass a variety of applications, including robotics, assembly line automation, conveyor systems, and machine control. Each of these applications leverages the synergy between electrical and mechanical systems to optimize manufacturing and production processes.

Robotics is one of the most prominent applications of electromechanical systems in industry. Automated robotic arms and machines are employed for diverse tasks such as welding, packaging, and material handling. By integrating electromechanical services, companies can achieve significant improvements in production speed and accuracy, leading to reduced operational costs and enhanced product quality. Robotics also contributes to a safer work environment, as these machines can undertake hazardous tasks that would otherwise pose risks to human workers.

Assembly line automation is another area where electromechanical services excel. The seamless integration of automated systems allows manufacturers to streamline their operations and reduce human error on production lines. This increased reliance on technology not only boosts productivity but also extends equipment longevity by minimizing wear and tear typically associated with manual labor. Moreover, the precise control over machinery ensures consistent product quality, which is crucial in meeting market standards.

Furthermore, conveyor systems, which are integral to material transport within facilities, illustrate the efficiency brought by electromechanical solutions. Implementing advanced conveyor systems enhances workflow, allowing for the smooth movement of goods and materials across production lines. This integration contributes significantly to overall operational efficiency, directly affecting lead times and inventory management.

Overall, the impact of electromechanical services in industrial settings manifests through enhanced productivity, improved safety, and increased equipment longevity. As industries continue to embrace these advanced technologies, the benefits will only become more pronounced, paving the way for future innovations in manufacturing processes.

Benefits of Electromechanical Services

Electromechanical services play a vital role in modern commercial and industrial establishments, offering numerous advantages that contribute to enhanced operational efficiency. One key benefit is improved performance. Systems that integrate both electrical and mechanical components are designed to work in harmony, resulting in streamlined processes. For instance, the automation of machinery through electromechanical systems allows for increased production rates and consistency in output quality, which is essential for meeting market demands.

Another significant advantage of electromechanical services is increased reliability. By employing advanced technologies, these systems minimize the risk of failure due to systemic polarization of mechanical and electrical components. This reliability translates into fewer operational interruptions, allowing businesses to maintain their competitiveness and profitability over time. As reported by a study conducted by a leading industry publication, companies implementing electromechanical solutions reported a 30% reduction in downtime, thereby showcasing the effectiveness of these systems.

Furthermore, the adoption of electromechanical services can lead to substantial reductions in maintenance costs. These integrated systems not only require less frequent maintenance but also enable predictive maintenance capabilities through data analytics. By anticipating potential issues before they escalate, companies can save significantly on repair costs and extend the lifespan of their equipment.

Improved safety standards constitute yet another benefit. Electromechanical services often incorporate safety features that adhere to industry regulations, ensuring a safer working environment for employees. Automation and precise control reduce the chances of human error, which contributes directly to enhanced safety practices. Notably, manufacturers have achieved up to a 40% decrease in workplace accidents after implementing these services.

Additionally, electromechanical systems can enhance energy efficiency. By optimizing operations and reducing waste, organizations benefit from lower energy expenses, which can impact the bottom line positively. Overall, the implementation of electromechanical services undoubtedly results in significant gains across various dimensions, making it a wise investment for forward-thinking businesses.

Challenges Faced in Electromechanical Service Implementation

Implementing electromechanical services within commercial and industrial establishments presents a unique set of challenges that can hinder operational efficiency. One of the primary obstacles is the integration of these systems with existing infrastructure. Many organizations use legacy systems that may not be compatible with the latest electromechanical technologies. This incompatibility can lead to increased downtime and higher costs as organizations must either upgrade their systems or develop custom solutions to ensure seamless operation.

Moreover, the demand for skilled labor in the electromechanical field cannot be overstated. The successful installation and maintenance of electromechanical systems require technicians with specialized training and knowledge of both electrical and mechanical principles. Finding and retaining such qualified personnel can be a significant challenge for businesses, especially in regions facing labor shortages in technical disciplines. This skill gap can lead to delays in project timelines and increased operational risks if inadequately trained individuals handle critical components.

Maintenance of electromechanical systems is another area of concern. These systems often require regular servicing to ensure optimal performance and longevity. However, many organizations underemphasize the importance of preventive maintenance, leading to unexpected failures that disrupt operations. In addition, as technology advances, older electromechanical systems may become obsolete, necessitating costly upgrades or replacements. Businesses must navigate the balance between adopting the latest technologies and maintaining existing equipment to avoid obsolescence while managing their budgets effectively.

Overall, while electromechanical services provide significant benefits, the integration difficulties, the need for skilled labor, maintenance challenges, and the threat of technological obsolescence can complicate their implementation, necessitating careful planning and strategic investment to overcome these hurdles.

Future Trends in Electromechanical Services

The field of electromechanical services is undergoing rapid transformation driven by technological advancements and emerging trends that are set to redefine the landscape of commercial and industrial applications. One of the most significant trends is the integration of the Internet of Things (IoT) within electromechanical systems. By utilizing IoT technology, devices can communicate and share data in real-time, enhancing operational efficiency and enabling predictive maintenance. This shift towards connected systems not only improves performance but also reduces downtime and associated costs.

Artificial Intelligence (AI) and machine learning are also playing crucial roles in the evolution of electromechanical services. These technologies support the development of smarter systems that can analyze vast amounts of data to optimize operations, improve reliability, and enhance decision-making processes. For instance, AI can be utilized to create algorithms that predict failure patterns in machinery, allowing for timely interventions that prolong equipment life and reduce unplanned outages. Machine learning models can learn from historical data, identifying trends and anomalies that assist in fine-tuning electromechanical processes.

Sustainable technologies are increasingly becoming a priority in electromechanical services, as businesses aim to reduce their environmental impact. Innovations such as energy-efficient motors and eco-friendly materials are being integrated into electromechanical designs. Sustainable practices not only comply with regulatory requirements but also resonate with consumers and stakeholders who are more conscious of environmental issues. As demand for green solutions continues to grow, we can expect further advancements that will enhance the performance and sustainability of electromechanical systems.

In conclusion, the future of electromechanical services is poised for dynamic change, propelled by advancements in IoT, AI, and sustainable technologies. These innovations will significantly impact how commercial and industrial establishments operate, paving the way for more efficient, reliable, and environmentally friendly solutions.

Choosing the Right Electromechanical Service Provider

Selecting a suitable electromechanical service provider is a critical decision for any commercial or industrial establishment. Several key criteria must be evaluated to ensure that the chosen provider meets the specific needs of the organization and can deliver high-quality services consistently. First and foremost, it is essential to consider the provider’s experience within the electromechanical sector. A company with a substantial track record demonstrates its ability to handle a variety of challenges and has likely developed robust solutions through practical application.

Technical expertise is another crucial factor. It is important to verify that the service provider possesses the necessary skills and qualifications in areas relevant to the specific electromechanical systems in use. Certifications, training, and specialized knowledge can indicate a provider’s competence and reliability. Additionally, the range of services offered should align with the organization’s requirements. This could include maintenance, repair, system integration, or even bespoke electromechanical system designs. A comprehensive service portfolio ensures that the provider can cater to any potential needs that may arise throughout the project lifecycle.

Customer support capabilities are equally significant. Effective communication and responsive support can greatly enhance the partnership, particularly during critical situations. Assessing customer reviews and testimonials can provide insights into the level of satisfaction previous clients have experienced. Lastly, industry-specific knowledge should not be overlooked. Providers with expertise in particular sectors, such as manufacturing, healthcare, or energy, are more likely to understand the unique demands and regulations associated with that industry, leading to more effective solutions.

To make informed decisions, organizations should conduct thorough evaluations of potential service providers, including interviews and site visits. This proactive approach will help identify the best electromechanical service provider suited to bolster operational efficiency.

Conclusion and Call to Action

Throughout this blog post, we have explored the essential role of electromechanical services in various commercial and industrial settings. These services encompass a broad range of applications, integrating mechanical systems with electronic controls to optimize functionality and enhance operational efficiency. From manufacturing processes to energy management, the implementation of electro-mechanical solutions can significantly improve productivity, reliability, and overall performance.

The versatility of electromechanical systems allows businesses to address unique challenges effectively. For instance, in automation, the synergy between mechanical components and electronic controls ensures precise operations, minimizing downtime and maximizing efficiency. Furthermore, the advancements in technology have led to the development of sophisticated electromechanical devices that can adapt to rapidly changing market demands, ensuring that industries remain competitive.

It is crucial for business owners and facility managers to recognize the importance of investing in electromechanical services. By assessing current systems and identifying areas where upgrades or new installations are needed, organizations can reap the benefits of improved energy efficiency, reduced operational costs, and enhanced safety standards. Whether it’s through upgrading existing equipment or integrating novel technologies, every step taken towards electromechanical optimization can have a lasting impact on an organization’s success.

As we conclude this overview, we encourage readers to critically evaluate their operational needs and consider how electromechanical solutions can play a vital role in achieving their objectives. Engaging with professionals in the field can provide valuable insights into the best strategies for implementation. Taking action now can lead to substantial improvements in operational capabilities and sustainability for the future.