How to Extend the Lifespan of Your Air Compressor: Essential Maintenance Tips

Introduction to Air Compressor Lifespan

Air compressors are versatile machines that play a crucial role in various industries, including construction, manufacturing, automotive, and home improvement. They work by converting power into potential energy stored in compressed air, which is then used to power a range of tools and equipment. Common uses of air compressors include supplying pressurized air to pneumatic tools, inflating tires, and powering spray guns. Their widespread applicability highlights the importance of understanding how to maintain them effectively to ensure optimal performance.

The lifespan of an air compressor can vary significantly based on its type, usage, and maintenance practices. Generally, these machines can last anywhere from 10 to 30 years if properly cared for. Neglecting regular maintenance, however, can lead to unforeseen breakdowns, diminished performance, and ultimately, costly repairs or replacements. Therefore, it is imperative that operators and owners prioritize the upkeep of their air compressors.

Regular maintenance routines are essential in extending the life of an air compressor. Tasks such as checking and replacing filters, draining moisture from the tank, and inspecting belts and hoses can significantly reduce the risk of malfunction. Adopting a proactive maintenance schedule not only enhances the efficiency of the air compressor but also aids in identifying potential issues before they escalate. This preventative approach serves to optimize operational performance and can lead to notable savings over time, both financially and in time lost due to unexpected downtime.

Understanding the importance of air compressor maintenance is pivotal for anyone relying on these machines for their operations. Implementing consistent care practices not only ensures high performance but also contributes to the longevity of these essential machines, making them a valuable investment for any business or individual.

Understanding Your Air Compressor Parts

To effectively maintain and extend the lifespan of your air compressor, it is crucial to understand its key components: the motor, pump, tank, and filters. Each of these parts plays an integral role in the overall functionality of the compressor, and familiarity with them will aid users in identifying specific maintenance needs.

The motor serves as the heart of the air compressor, converting electrical energy into mechanical energy to power the pump. This component is essential for starting the compression process, and its efficiency directly influences the overall performance of the compressor. Regular checks on the motor for signs of wear, such as unusual noises or overheating, can help detect potential issues early.

The pump is another critical element, tasked with compressing the air and storing it in the tank. It works by creating high pressure, which allows the stored air to be used effectively across various applications. Understanding how the pump operates can help users recognize when it’s operating inefficiently, leading to increased energy consumption or reduced output pressure.

The tank stores the compressed air and plays a vital role in maintaining consistent pressure for tools and equipment. Over time, tanks can accumulate moisture and may develop rust, which can affect their integrity. Conducting regular inspections for corrosion and ensuring proper drainage of moisture can significantly prolong the tank’s lifespan.

Finally, filters are essential for maintaining air quality and protecting internal components from harmful debris. Air filters should be checked and cleaned regularly to ensure unrestricted airflow and optimal performance. Moreover, replacing worn-out filters is crucial in maintaining efficiency and preventing damage to other parts.

By gaining insight into these fundamental parts of an air compressor, users can adopt proactive maintenance strategies, ensuring greater reliability and longevity for their equipment.

Regular Cleaning and Inspection

Maintaining an air compressor requires consistent attention, with regular cleaning and inspection being critical components of effective upkeep. These practices are essential for ensuring that the air compressor operates efficiently and safely, which in turn extends its overall lifespan. One of the fundamental steps in this process is checking for leaks. A small leak can lead to significant drops in pressure and energy inefficiency, resulting in further wear on the compressor. Regular inspections should include a thorough examination of connections, hoses, and valves for any signs of air loss.

Another vital aspect of the maintenance routine is the cleaning of air filters. Clogged or dirty filters restrict airflow which not only compromises performance but also forces the air compressor to work harder, causing unnecessary strain on the unit. It is advisable to inspect the filters monthly and clean or replace them as needed. Additionally, ensuring that the compressor is free from dirt and debris is imperative. Dust and grime can accumulate, encasing the unit, which can lead to overheating and malfunctioning. Keeping the compressor clean also contributes to a safer working environment.

Regular inspection intervals, ideally every few months, should include checking coolant levels, belt tension, and electrical connections. Furthermore, recording the findings from these checks can help identify trends over time, enabling proactive rather than reactive maintenance. By taking these steps—conducting regular cleaning and in-depth inspections—air compressor owners can prevent many common issues that lead to costly repairs. Essentially, investing time in these practices not only ensures optimal performance but also significantly prolongs the life of the air compressor.

Oil Changes and Lubrication

The importance of regular oil changes and proper lubrication cannot be overstated when it comes to the longevity and efficiency of your air compressor. Oil serves multiple critical functions, including reducing friction between moving parts, dissipating heat, and preventing corrosion. Without sufficient lubrication, an air compressor can experience increased wear and tear, resulting in reduced performance and a shorter lifespan.

Generally, it is advisable to check the oil level on a monthly basis, especially for compressors that undergo frequent use. The frequency of oil changes, however, may vary depending on the specific model and the operating conditions. For instance, if the compressor is being utilized in a dusty or dirty environment, more frequent oil changes may be necessary to maintain optimal performance. As a rule of thumb, changing the oil every 50 to 100 operating hours is a good guideline, but it is essential to consult the manufacturer’s recommendations for your specific unit.

When selecting oil for your air compressor, it is crucial to use the type that is explicitly recommended by the manufacturer. Typically, air compressor oil will either be non-detergent petroleum oil or synthetic oil. Non-detergent oils are suitable for most standard compressors, while synthetic oils offer enhanced performance and protection against extreme temperatures. Make sure to replace the oil with the proper viscosity grade to ensure that the compressor operates efficiently.

Lubricating various moving parts within the air compressor is equally essential. Pay special attention to components such as the piston rings and bearings, which require adequate lubrication to function correctly. Using a quality grease and applying it at regular intervals can significantly decrease friction, enhancing the compressor’s efficiency and extending its lifespan. Regular maintenance of oil and lubrication not only optimizes performance but also safeguards your investment in the air compressor.

Monitoring Pressure and Temperature Levels

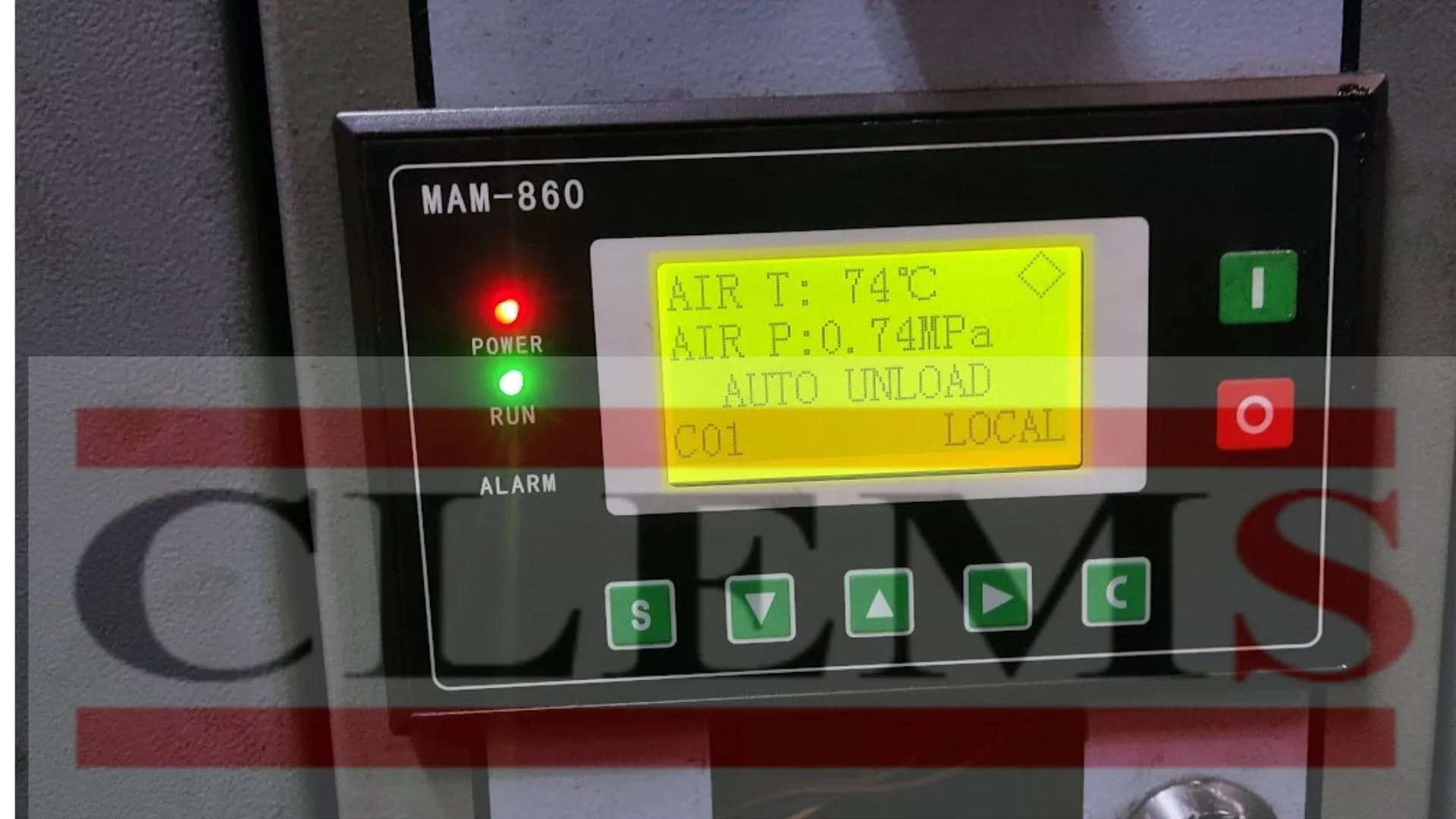

Maintaining the efficiency and longevity of an air compressor significantly relies upon the careful monitoring of pressure and temperature levels. Regularly supervising these critical parameters ensures that the compressor operates within its optimal settings, thus preventing potential damage and extensive repair costs. The pressure gauge is a vital tool in this process, allowing users to observe the system pressure and make necessary adjustments to avoid overloading the compressor. It is essential to ensure that the working pressure aligns with the manufacturer’s recommended specifications for optimal performance.

Temperature monitoring is equally important, particularly for preventing overheating, which can lead to severe mechanical failures. Air compressors can generate substantial heat during operation, and exceeding the recommended temperature range can result in component wear and reduced efficiency. Utilizing built-in temperature gauges or external monitoring devices is advisable. Setting alerts for anomalies in pressure or temperature can enhance your maintenance routine, enabling immediate corrective actions before issues escalate into significant damage.

When an air compressor operates at pressures or temperatures outside recommended limits, various adverse effects can arise. For instance, excessive pressure may lead to increased wear on seals and gaskets, raising the likelihood of leaks and malfunctions. Conversely, low pressure could hinder the equipment’s ability to function effectively, leading to subpar performance in tasks that require consistent airflow. Understanding these dynamics can help operators maintain a balanced and efficient system.

In summary, diligent monitoring of pressure and temperature levels is vital for the optimal operation of an air compressor. By implementing regular checks and utilizing appropriate monitoring equipment, users can prevent potential downtime and extend the unit’s lifespan significantly. Prioritizing this maintenance aspect will ultimately lead to a more efficient and reliable air compression system.

Drain the Tank Regularly

One of the essential practices for maintaining your air compressor is to drain the tank regularly. Over time, moisture builds up in the tank due to the compressed air process, which naturally contains water vapor. When this moisture accumulates, it can lead to significant issues such as corrosion, rust, and other internal damages that might compromise the compressor’s efficiency and longevity. Such damage can result in costly repairs or even necessitate a complete replacement of the unit.

To prevent these adverse effects, it is advisable to routinely drain the air compressor tank. The frequency of this maintenance task often depends on your usage level. For compressors that are used daily or for extensive periods, it may be necessary to drain the tank after each use. Conversely, if the compressor is used infrequently, a weekly or bi-weekly schedule might suffice.

To drain the tank effectively, follow these step-by-step instructions:

- First, turn off the air compressor and unplug it from the power source to ensure safety.

- Next, release the air pressure in the tank by pulling the pressure relief valve, which will minimize the risk of injury due to sudden air release.

- Locate the drain valve, often found at the bottom of the tank, and place a container beneath it to catch the moisture that will flow out.

- Open the drain valve slowly to allow the trapped moisture and air to escape. You should expect a mix of water and compressed air to emerge.

- Once all moisture has been drained, close the valve securely to maintain the integrity of the tank.

- Finally, check for any leakage around the valve and ensure the tank is properly resealed before powering it back on.

Incorporating this practice into your maintenance routine will significantly enhance the durability and performance of your air compressor, allowing it to serve you efficiently for years to come.

Replacing Worn Parts Timely

Air compressors play a pivotal role in various applications, and ensuring their longevity is paramount. One of the critical aspects of maintenance is the timely replacement of worn parts. Neglecting this essential practice can lead to more severe issues, ultimately resulting in costly repairs or even the need for a complete replacement of the compressor unit.

There are several components within an air compressor that are particularly susceptible to wear and tear over time. Belts, for instance, can become frayed or stretched, leading to inefficient operation and increased strain on the motor. Regular inspection for signs of damage, such as cracks or visible fraying, is crucial. If you observe these issues, it is prudent to replace the belts to maintain the compressor’s performance and efficiency.

Filters also play a vital role in maintaining air quality and system efficiency. Clogged or dirty filters can impede airflow, leading to overheating and decreased performance. During routine maintenance checks, it is essential to inspect filters regularly and replace them as needed, adhering to manufacturer recommendations regarding replacement frequency. Keeping filters clean not only extends the lifespan of the compressor but also ensures optimal performance.

Another component to keep a watchful eye on is the hoses. Hoses are responsible for transmitting air from the compressor to the tools or equipment they supply. Inspect them for any signs of cracking, bulging, or leaks. Even small leaks can lead to significant losses in pressure and efficiency, which can ultimately harm the compressor’s health. If you notice any signs of wear, it is advisable to replace the hoses promptly to prevent any further potential damage.

In conclusion, proactively replacing worn parts is a fundamental aspect of air compressor maintenance. Regularly assessing belts, filters, and hoses during routine checks can significantly enhance the operational efficiency and prolong the lifespan of your air compressor, safeguarding your investment for years to come.

Using Your Compressor Correctly

A crucial aspect of extending the lifespan of your air compressor is to utilize it correctly. Air compressors are designed to operate efficiently within specific limitations; exceeding these limits can lead to premature wear and tear. Therefore, understanding load management is essential. It is important to match the compressor’s output with the requirements of the tools you are using. If the compressor is consistently working harder than intended, it may overheat or fail, shortening its operational life.

Moreover, attention to pressure limits is vital. Every air compressor has a recommended pressure range, which is typically indicated in the owner’s manual. Regularly operating the compressor at pressures beyond this range can strain the internal components and lead to failures. Ensure that you frequently monitor the pressure levels and make adjustments as needed to stay within the prescribed limits. Using the compressor within its optimal range significantly contributes to its longevity.

Another critical component of correct usage is understanding the duty cycle of your compressor. The duty cycle refers to the ratio of operational time to rest time. For instance, a compressor with a 50% duty cycle should not operate for more than 30 minutes at a time if given 30 minutes of rest. Continuous reliance on the compressor without proper intervals can lead to overheating and potential damage. Be mindful of your model’s specifications regarding its duty cycle and allow for adequate cooling periods between uses.

In conclusion, using your air compressor within its designed parameters, keeping an eye on pressure limits, and respecting the duty cycle will collectively contribute to its longevity. Proper operational habits not only enhance performance but also minimize repair costs and extend the overall lifespan of the machine. Adopting these practices can ensure that your air compressor serves you effectively for years to come.

Professional Maintenance Services

Hiring professional maintenance services for air compressors can significantly enhance the longevity and efficiency of the equipment. While many air compressor owners are capable of performing basic upkeep, there are instances when consulting a trained technician becomes essential. These professionals possess specialized knowledge and experience that enable them to identify and address complex issues that may not be apparent to the untrained eye. For instance, signs of wear and tear, unusual noises, or diminished performance may warrant a professional assessment to prevent further damage.

Typical services provided by these experts include comprehensive inspections, diagnostics, and repairs. During a routine maintenance visit, a technician may check for air leaks, inspect hosesand belts, and assess the overall operational integrity of the compressor. They often perform tasks such as changing oil, cleaning air filters, and replacing worn-out parts. By addressing these issues proactively, technicians help to avoid costly breakdowns and ensure that the air compressor functions at peak efficiency.

Moreover, regular professional maintenance can complement an owner’s routine upkeep efforts. While owners can conduct basic maintenance tasks such as draining the tank or replacing filters, technicians can provide a deeper level of care that includes testing for optimal performance, calibrating settings, and conducting thorough system evaluations. This partnership between the owner and the maintenance service fosters a holistic approach to equipment management, reducing downtime and extending the compressor’s lifespan. In conclusion, investing in professional maintenance services is a prudent choice for any air compressor owner looking to protect their investment and ensure consistent operational efficiency.